History

History by generation

History by generation

Contents Shortcuts List

Transition to Eco-friendly Energy Company (2020~)

2021, Construction of Korea’s Largest 3D Printing Fabrication Facility

Doosan Heavy has been applying 3D printing technology since 2014 in an effort to establish

a most advanced manufacturing system for power plant components, such as gas turbines.

The company currently owns a total of five metal 3D printers and also has a 3D printing fabrication shop,

the largest in Korea, built on its premises. Doosan aims to create greater business synergy

by widening the scope of application to other sectors, such as the aviation and national defense sectors,

in addition to the power plant sector.

2021, Diversification of SMR Business

Doosan has diversified its SMR business by strengthening cooperation in this field,

such as through the additional investment made in the US-based NuScale Power and by signing a service agreement

for the design engineering of nuclear components with the US-based X-energy, a company whose SMR development is

based on high-temperature gas reactor technology.

2021, Signing of Equipment Supplier Contract for Korea’s Largest Offshore Wind Farm

Doosan Heavy, the company with the longest track record in Korea’s offshore wind power sector,

has once again proven its competitiveness in this field by winning the contract to supply the equipment

for Korea’s largest offshore wind farm, the 100MW Jeju Hallim Offshore Wind Farm. Doosan has plans to

supply 18 units of 5.56MW offshore wind turbines going forward.

2021, Active Diversification of Hydrogen Business Portfolio

Doosan is stepping up efforts to diversify its hydrogen energy business. The plan is to acquire

the technology and track record for producing clean hydrogen, such as blue and green hydrogen,

successfully develop a hydrogen gas turbine and build up the company’s hydrogen-related equipment business,

all of which will be pursued to solidify Doosan’s position as market leader in the hydrogen business.

2021, Construction of Wind Turbine Shop #2 in Changwon

We completed construction of the Wind Turbine Shop #2 at our headquarters in Changwon to effectively prepare

for the rising number of orders for offshore wind turbines and the manufacturing of 5.5MW wind turbines.

With the existing Wind Turbine Shop #1 and the opening of Wind Turbine Shop #2, Doosan is now in a position

to produce 30 units of offshore wind turbines annually.

2021, Active Exporting of Nuclear Components to Overseas Market

Doosan made great headway in the exporting of nuclear equipment, such as becoming the first company

in Korea to export spent-fuel storage casks to the US and signing a supplier agreement for the automatic

seismic trip system(ASTS), a key component of nuclear power plant’s instrumentation & control (I&C) system,

with China.

2020, Construction Initiated for Gimpo CHP Plant, a Demonstration Site for Doosan’s Large Industrial Gas Turbine

Construction has commenced for the Gimpo Combined Heat & Power (CHP) Plant project, which involves installation of

the large industrial gas turbine that was locally manufactured and developed by Doosan.

The development of the gas turbine established Doosan as the fifth company in the world to successfully

accomplish such a feat by itself. Doosan secured the opportunity to take part in the demonstration of a large

gas turbine when it signed a gas turbine supplier agreement with Korea Western Power.

Korea Western Power will be providing Doosan with useful operating and technical information acquired

from the demonstration project to facilitate a successful market entry for the next generation Korean-style

combined cycle power plant model that is developed.

2020, Offshore Wind Power Emerges as Doosan Heavy’s New Growth Engine

Doosan is preparing to penetrate in full force the market for offshore wind power by establishing

this area as its new growth engine in line with the government’s Green New Deal initiative.

As the leading Korean company in the offshore wind power sector, we intend to actively participate

in the Green New Deal initiative and contribute to promoting the growth of the domestic offshore wind power market.

2020, Min. KRW 1.5 trillion worth of SMRs to be Supplied to US and Global Markets

The SMR(small modular reactor) project in the States, which Doosan is participating in as the main equipment supplier,

is gaining momentum. The U.S. Nuclear Regulatory Commission (NRC) completed the Phase 6 review—the last and final

phase—of the Design Certification Application for the SMR developed by the U.S. based NuScale, with which Doosan Heavy

has a strategic partnership. Doosan will supply at least US$1.3 billion worth of major SMR equipment to the US and other

global markets through NuScale.

2020, Contract Signed to Build Korea’s First Hydrogen Liquefaction Plant

Doosan will be constructing Korea’s very first hydrogen liquefaction plant, together with Gyeongnam Province,

Changwon City and Changwon Industry Promotion Agency (CWIP). Doosan will be building the plant, which is

to have a daily production capacity of 5 tons of liquefied hydrogen, within the grounds of its Changwon

plant in Gyeongnam by 2022. The plant will start commercial operation in 2023, and the liquefied hydrogen

will be supplied to hydrogen charging stations nationwide.

2020, Expansion of Hydropower Business

Doosan is expanding its hydropower business by participating in the development of the Upper Trishuli-1

hydropower plant in Nepal and a hydropower plant in Pakistan. Furthermore, Doosan signed an MoU with Korea

Western Power to cooperate on developing a hydropower plant in Phou Ngoy, Laos, while also signing a MoU

with Korea Midland Power to jointly develop overseas hydropower markets.

The Path to Global Leadership (2019 ~ 2008)

2019, Participated in Korea’s First Hydrogen Liquefaction Demonstration Project

Doosan plans to supply Korea’s first hydrogen liquefaction plant to support Changwon City’s project to build

a demonstration site for hydrogen energy circulation and storage systems.

2019, Acquired Korea’s First International Certification for 5.5 MW Offshore Wind Power System

Doosan became the first Korean company to receive the “Type Certificate” for its 5.56W offshore wind power system from the UL DEWI-OCC,

an international certification agency. The new system boasts of having the largest capacity of any model in Korea’s wind power market.

2019, Set to Complete Development of Large Gas Turbine for Power Generation … Korea to Become Fifth Country to Own Independent Model

Doosan had held the final assembly event at the head office in Changwon for the first large gas turbine for power generation.

It’s currently being developed as part of a national project sponsored by the Ministry of Trade, Industry and Energy and the Korea

Institute of Energy Technology Evaluation and Planning. Once it has passed an in-house performance test in 2020, Korea will become one

of the five countries along with the United States, Germany, Japan, and Italy to have secured independent gas turbines for power generation.

2019, Set to Expand Gas Turbine Service Business at Home and Abroad

Doosan signed a memorandum of understanding with MCV, American private energy firm, to extend cooperation

in maintenance and improvement of MCV’s gas turbines. With the MOU, Doosan expects to strengthen its

foothold in gas turbine aftermarket business. In the Korean domestic market, it had won a contract

to maintain the exhaust cylinders of three gas turbines installed at Units 4 to 6 of the Ulsan Oil Fired

& C.C Power Complex. The order was a follow-up to the successful maintenance of the gas turbine exhaust

cylinder of Unit 3 of the same complex.

2019, Materialize the First Entry into Small Modular Reactor Market in USA

Doosan completed equity investment in NuScale Power for its small modular reactor (SMR) technology

and executed a business collaboration agreement with NuScale Power for the NuScale Power Module™ (NPM)

and other equipment supply. Doosan plans to supply equipment worth at least $1.3 billion to NuScale

Power for both U.S. and global deployment of the NuScale power plant.

2018, Entered Wind Power Market in Vietnam

Doosan Heavy Industries & Construction signed agreements with local companies in Hanoi to lay the

groundwork for developing the wind power market in Vietnam. Doosan signed a business agreement with

Vietnam’s state power company Vietnam Electricity (EVN) to develop an energy storage system (ESS)-linked

3MW offshore wind power demonstration project, marking a milestone in the company’s renewable energy business.

2018, Successively Won Orders for Energy Storage System (ESS) at Home and Abroad

Doosan Heavy Industries & Construction has recently been successively winning contracts for energy storage system (ESS) projects.

The company signed a contract with SK E&S to deliver a power demand management ESS facility. Furthermore,

with Doosan Heavy’s US-based subsidiary, Doosan GridTech, also winning a contract together with Consumers Energy to implement

an ESS at a substation in Kalamazoo, which is located in the southwestern part of Michigan, the company is effectively building

up its competitiveness in both the domestic and overseas markets.

2018, Doosan to develop Korea’s largest 8MW offshore wind power system

Doosan Heavy Industries & Construction (DHIC) has been selected as the main contractor for

the 8MW Large-Capacity Offshore Wind Power System Development project, a state project sponsored

by the Korea Institute of Energy Technology Evaluation and Planning (KETEP). With this new development,

the Company will be able to expand its wind power system lineup to 8 MW from the current 3 MW and 5 MW lineup.

The development of this model will help aggressively penetrate the overseas wind power market, where the

growing trend is for large scale models and it will also help increase the share of local supplier products

in the Korean market, where foreign models currently account for more than half of the market share.

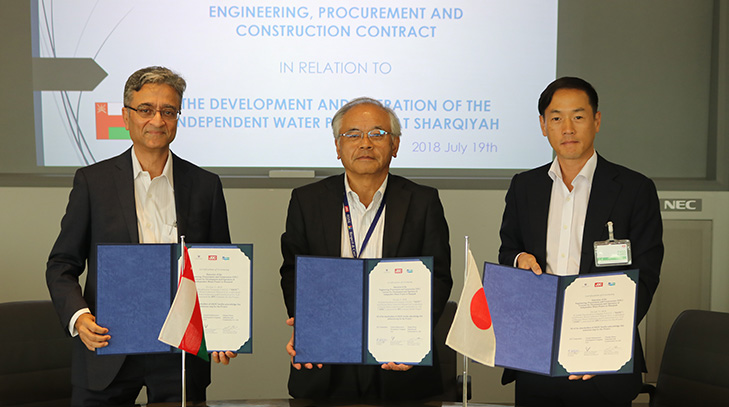

2018, Secured an order for a seawater desalination plant in Sharqiyah, Oman

Doosan took part in a 230 billion won desalination project in Sharqiyah, Oman. With the partners in its consortium,

Doosan will carry out the engineering, procurement, and construction for the project. Furthermore, with this project,

the Company has broadend its business scope from construction to development and operation.

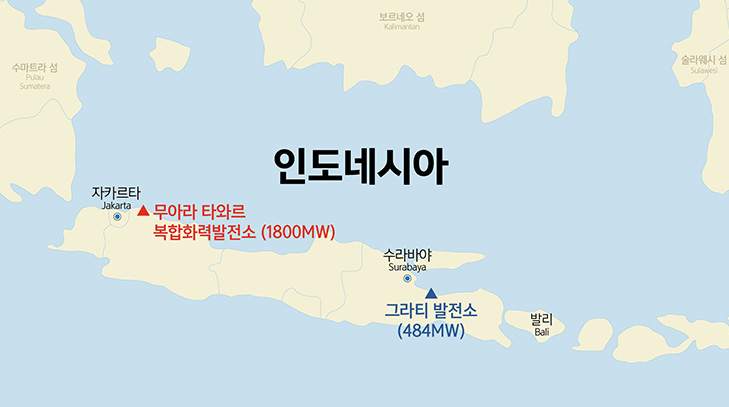

2017, Doosan to Upgrade Indonesian Power Plant

Doosan Heavy Industries & Construction and its consortium partner PT. Hutama Karya, an Indonesian

state-owned construction company, received a 470 billion won order from PT. Perusahaan Listrik Negara (PLN),

an Indonesian government-owned sole electricity utility company, for Muara Tawar Combined Cycle Power Plant.

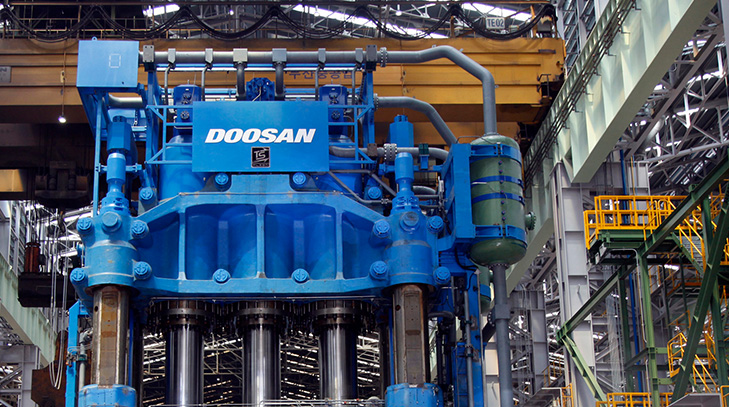

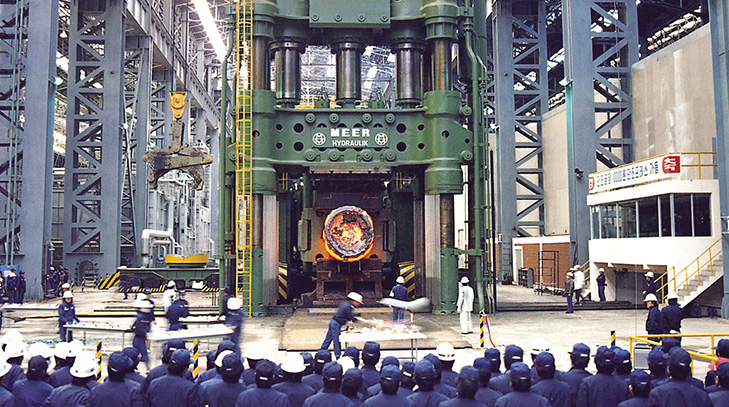

2017, Installed 17,000-ton forging press

Doosan Heavy Industries & Construction held a ceremony to celebrate the installation of a new 17,000-ton

forging press – the world’s largest to date – at the forging plant of its manufacturing complex in Changwon,

South Gyeongsang province in South Korea. The new 17,000-ton forging press is 29 meters tall and 9 meters wide,

and it can forge steel ingot with the strength equivalent to 240,000 men pressing on the metal at the same time.

It is currently the world’s biggest four-pillar type forging press to date.

2017, Won ‘Desalination Company of the Year’ Award from Global Water Intelligence

Doosan Heavy Industries & Construction was named as the winner of the ‘Desalination Company of the Year’ award by

Global Water Intelligence (GWI), one of the industry’s leading research organizations. The prestigious award is a clear

recognition of Doosan Heavy’s leading contribution to the desalination industry.

2017, Acquired 5.5MW Offshore Wind Power Technologies

Doosan Heavy Industries & Construction signed a contract to acquire the 5.5MW offshore wind power technology

developed by Hyundai Electric & Energy Systems. The 5.5MW wind turbine boasts of the largest capacity among domestic

products of its kind. The system was installed in Gimnyeong Pilot Complex on Jeju Island and has been in operation

for about three years.

Completed Acquisition of US Gas Turbine Service Firm ACT

Doosan Heavy Industries & Construction finalized the acquisition of ACT Independent Turbo Services (ACT),

a US gas turbine service company, and established Doosan Turbomachinery Services. With the acquisition,

Doosan will secure not only professionals and facilities specializing in gas turbine services,

but also order backlogs and know-how; thus instantly entering the US gas turbine market with a capacity of 16GW per annum.

2016, Rabigh 2 Project Won “Power and Desalination Project of the Year Award”

The Rabigh 2 project implemented by Doosan Heavy Industries & Construction in Saudi Arabia was

given the “Power and Desalination Plant of the Year award” by Middle East Economic Digest (MEED),

an economic magazine in the Middle East.

2016, Acquired 1Energy Systems, US Energy Storage System Firm

Doosan Heavy Industries & Construction acquired 1Energy Systems (now known as Doosan GridTech),

a company that possesses fundamental technology in ESS (energy storage system) control systems in July,

and won the first ESS order in the US in October. Doosan Heavy Industries & Construction has secured

the industry’s best competitiveness in the ESS business and laid the foundation for expanding businesses

to include the Microgrid market.

2016, Earned Highest Grade in Shared Growth Index

Doosan Heavy Industries & Construction received the top grade, the highest honor, in the shared growth index

assessment 2015 conducted by the National Commission for Corporate Partnership. Doosan Heavy Industries &

Construction acquired the highest grades in “track records in the implementation of fair trade and shared growth”

and “assessment of perception among SMEs” that surveyed partner firms; thus earning recognition as a company that

strengthens shared growth with business partners.

2016, Started Commercial Operation of Taean IGCC Plant

Taean Integrated Gasification Combined Cycle (IGCC) Plant, which was supplied by Doosan Heavy Industries & Construction

through the EPC method, started commercial operation in August. The company became the seventh in the world to

commercialize an IGCC plant. A project implemented as part of the government’s renewable energy R&D project in 2006,

the Taean IGCC plant is an outcome of the project to develop technology for the first

“Korean standard 300MW-class IGCC demonstration plant.”

2016, Launched Korea’s First Commercial Offshore Wind Farm

Jeju Tamna Offshore Wind Farm, Korea’s first commercial offshore wind power complex, started operation on September 29.

Doosan Heavy Industries & Construction constructed 10 units of 3MW-class offshore wind power generator in the complex

through the EPC method, ushering in the era of offshore wind power in Korea.

2016, Won Successive Large EPC Projects in India, Saudi Arabia, etc.

Doosan Heavy Industries & Construction won large-scale EPC projects in succession including the 2.8 trillion won

Obra-C and Jawaharpur projects in India, the one trillion won Fadhili project in Saudi Arabia, and the 950 billion won

Subic Redondo project in the Philippines in the second half of 2016, solidifying its position in the global power market.

2015, Achieved 50 Million Safe Man Hours

Doosan’s Rabigh 2 thermal power plant construction project which was constructed for SEC has achieved 50 million safe man-hours.

Doosan established an advanced EHS culture through systematic and differentiated EHS activities in Saudi Arabia.

The record of 50 million safe man-hours is the longest duration of accident-free operation among any global project

Doosan has performed to date.

2015, Won Song Hau 1 Thermal Power Plant Project in Vietnam

Won an order for the 1,200MW Song Hau coal-fired power plant this past April. As the main EPC contractor,

Doosan will supply the main equipment of the plant including boilers and turbines as well as construct the plant.

The plant is expected to contribute to easing power shortages in southern Vietnam.

2015, Achieved Cumulative Production of 30 Reactor Vessels and 100 Steam Generators

Started manufacturing reactor vessels in the early 1980s beginning with Hanbit unit 1 and produced Doosan’s 30th reactor

vessel this summer, the VC Summer unit 3. Moreover, last May Doosan delivered their 100th steam generator after

30 years of manufacturing nuclear steam supply systems.

2015, Ras Al Khair Wins ‘2015 Desalination Plant of the Year’

The Ras Al Khair Ph.1 seawater desalination plant, constructed by Doosan Heavy Industries & Construction in Saudi Arabia,

was awarded ‘Desalination Plant of the Year’ at the 2015 Global Water Awards hosted by the Global Water Intelligence

(GWI) in Zurich, Switzerland. GWI is a world-renowned specialty journal on water.

2015, Won Order for Construction of Shin-Kori Nuclear Power Plant Units 5 and 6

Has successfully won an order for construction of the Shin-Kori nuclear power plant units 5 and 6 this past June.

Doosan had also signed a deal to supply the main nuclear equipment to the plant in 2014.

This latest contract helps strengthen Doosan’s capabilities as a leading nuclear power plant facility maker.

2015, Sewage Treatment Plant Orders from Oman and England

Won the phase 2 of the Al-Ansab sewage treatment plant from Oman, the first order in the Middle East,

and Doosan Enpure, the company’s subsidiary, won the phase 2 of Bellozanne sewage treatment works replacement plant in England.

2015, Became Main Business Partner of ESS under Smart Grid Implementation Project

Became the main business partner to deliver the energy storage systems (ESS) under the 2015 Smart Grid Implementation Project,

which was hosted by the Korea Smart Grid Institute. With its first achievement of supplying 1MW ESS facilities with Kwangjin Engineering,

Doosan will also supply the main equipment for the 2.4MW ESS with Korea Power Exchange (KPX), the largest output among all the ESSs

installed in a single building in Korea to date.

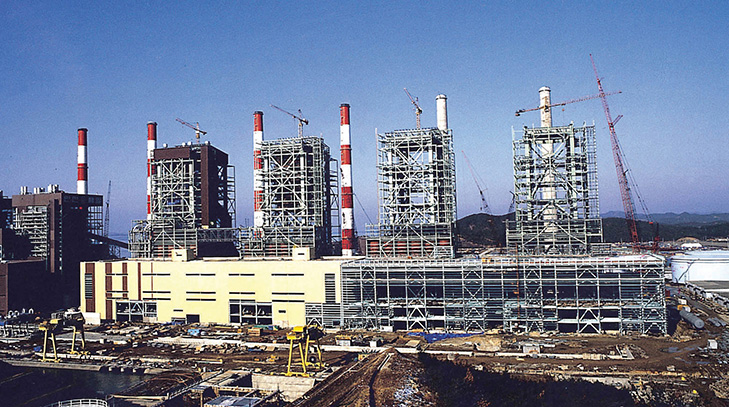

2015, Won Orders for 1000MW-Class Thermal Power Plant Projects at Home

Starting with its first project to supply the main equipment for Shin Boryeong thermal power plant in 2013,

Doosan has successfully won orders for 1000MW-class thermal power plant projects at home,

including the Gangneung Anin thermal power project in April, the Shin Seocheon thermal power project in November

and the Goseong Hai thermal power plant project in December.

2015, Entered into South African Power Market

Laid foundations to expand its South African power market by making a contract to refurbish the aged facilities

at the Morupule A power plant in Botswana. Through efforts to expand and diversify its markets,

Doosan has successfully made inroads into new markets, including South Africa and Turkey this year.

2014, Integrated Energy System Order for Dongtan 2 New City

Signed a KRW 380 billion contract by Korea District Heating Corporation to supply the integrated energy systems to be built in Dongtan 2 New City,

a city being created in Hwaseong, just south of Seoul in South Korea.

Nuclear Equipment Order for Shin-Kori Units 5 and 6

Signed a KRW 2.3 trillion contract to supply main equipment for Shin-Kori Nuclear Power Plant Units 5 and 6 together

that adopt Korean-designed APR 1400, boasting of significantly enhanced safety.

2014, Enlistment in Dow Jones Sustainability Index

Received a certificate of enlistment in the Dow Jones Sustainability Index (DJSI) at the “2014 DJSI International Conference.”

DJSI is a global standard that evaluates the sustainability of management by comprehensively assessing companies in the economic,

environmental, and social aspects, and the company has been enlisted in Korea Class.

2014, 3MW Wind Turbine Recognized as World-Class Product

The company’s WinDS3000, a 3MW-class offshore wind turbine was chosen as the World-Class Products.

2014, Won Nghi Son 2 Thermal Power Plant Project in Vietnam

Won an order for the 1330MW (665MWX2) Nghi Son 2 thermal power plant project in Vietnam.

This is the company’s 3rd EPC contract following its Mong Duong 2 and Vinh Tan 4 thermal power plant projects in Vietnam.

2014, Entered into the Central Asian Power Market with Karabatan Plant in Kazakhstan

Won the first order for the 310MW Karabatan combined cycle thermal power plant project in Kazakhstan,

paving the way for its advancement into the Central Asian power market.

2013, Entered into the Latin American Market with Escondida Plant in Chile

he Escondida Desalination Plant, the largest RO-mode project in Latin America,

will produce 220,000 tons of freshwater a day that can be used by 550,000 people simultaneously.

The project is the first of its kind in a region other than the Middle East for the company.

2013, Shin-Boryeong Thermal Power Plant Units 1 & 2 Orders

Won an order worth KRW 850 billion to supply boilers and turbine generators for the Shin-Boryeong thermal plant units 1 and 2.

The plants are the first 1000 MW Ultra-Supercritical (USC) coal-fired thermal power plants developed with domestic technology.

These eco-friendly and high-efficiency power plants are more efficient than conventional coal-fired thermal power plants

and generate less carbon dioxide.

2013, Won Vinh Tan 4 Thermal Power Plant Project in Vietnam

Won an EPC contract for the Vinh Tan 4 coal-fired thermal power plant to be built in Binh Thuan,

some 230km east of Ho Chi Minh City. As an EPC contractor, Doosan is to lead the entire process

from equipment manufacture, installation and trial operation.

2013, Integral Heads for Major Nuclear Equipment

The company’s integral heads and excitation systems for major nuclear equipment were chosen as the World-Class Products.

2012, Announced “The Doosan Way” for the Next 100 Years

Announced “The Doosan Way,” Doosan’s corporate philosophy to continue the remarkable transformation and

success of the past 100 years into the next 100 years.

2012, Bulk Order Ⅱ from India

Indian subsidiary DPSI won orders from India’s state-owned power utility NTPC,

including three 800 MW boilers for the Kudgi project in Karnataka and two additional

800 MW boilers for the Lara project in Chhattisgarh.

2012, Acquired Enpure of the UK

Strengthened competitive edge in water treatment business by acquiring UK-based Enpure (currently Doosan Enpure)

to gain access to world-class preconditioning equipment design as well as water treatment technology.

2012, Yanbu Phase 3 Desalination Plant Order from Saudi Arabia

The Yanbu Phase 3 Desalination Plant valued at KRW 1.1 trillion in Saudi Arabia supplies water to the neighboring city of

Media using an MSF method. The plant produces 550,000 tons (121MIGD) of freshwater that can be used by 1.8 million people simultaneously.

(Photo: Yanbu Phase 2 MED Desalination Plant completed in 2013)

2012, Commercial Steam Generator Chosen as World-Class Product

The company’s steam generators and super-large forged backup roll for plate rolling mill were chosen as the World-Class Products.

2011, Chennai Works and Lentjes Acquisitions

Acquired India-based boilermaker Chennai Works (currently Doosan Power Systems India) in February,

gaining competitive edge in the Indian market. In November, subsidiary Doosan Power Systems (DPS)

acquired German-based Lentjes (currently Doosan Lentjes), gaining access to eco-friendly technologies,

such as Circulating Fluidized Bed (CFB) boilers.

2011, First Major MED Desalination Plant Order

Won the Yanbu Phase 2 Expansion (15 MIGD) EPC desalination project from Saline Water Conversion Corporation (SWCC)

in Saudi Arabia. This made the company the first in the global water industry to secure a project and technology

portfolio spanning the top three major desalination technologies – Multi-Stage Flash (MSF), Reverse Osmosis (RO)

and Multi-Effect Distillation (MED).

2011, 3MW Wind Turbine International Certification

The company’s 3MW wind turbine system, launched as a government project in 2006, won international

type certification from DEWI-OCC of Germany, paving the way for overseas sales.

2011, Taean IGCC Demonstration Plant Order

Signed an agreement on November 15 on the construction of 300 MW Taean IGCC project,

Korea’s first integrated-gasification combined-cycle demonstration plant.

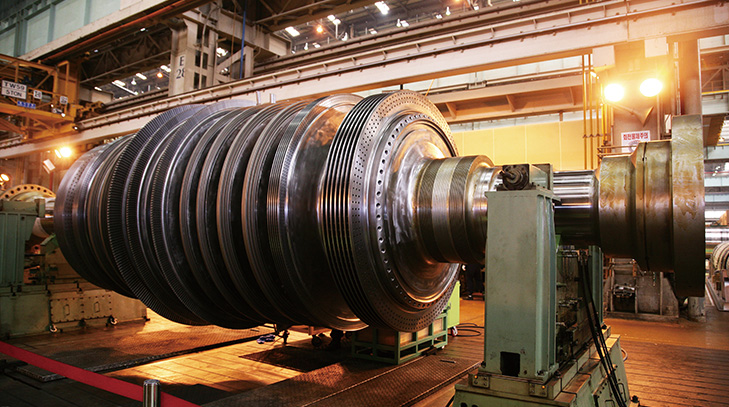

2011, Commercial Nuclear Reactor Chosen as World-Class Product

Nuclear reactors, turbine-generator rotor shafts and oil-fired boilers were additionally

chosen as World-Class Products for commercial nuclear power plants.

2010, Established Doosan Power Systems (DPS)

In February, 2010, Doosan Power Systems was formed to coordinate the operations of Doosan Babcock

of the UK and Skoda Power of the Czech Republic, providing total power solutions to Europe and the Americas.

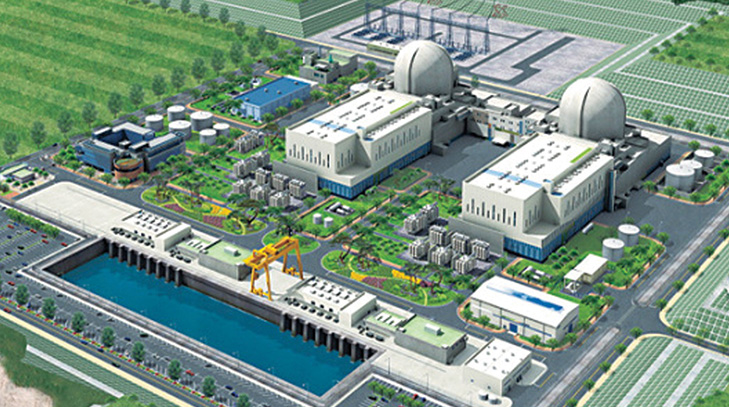

2010, APR1400 Nuclear Equipment Order from the UAE

Participated in a consortium led by Korea Electric Power Corporation (KEPCO) that won the US$ 4 billion

project in the UAE, in which the company will supply major equipment for APR1400 nuclear units.

The project is the company’s largest accomplishment since it entered the nuclear power plant business.

2010, Vietnam Mong Duong 2 Thermal Plant Order

Won a US$ 1.3 billion order for the Mong Duong II thermal project in Vietnam from AES-VCM in December 2010.

In the same month, the company also signed a framework agreement with the government of Vietnam to serve

as the sole technical partner for a national project to localize equipment production for 600 MW coal-fired thermal plants.

2010, Winning Record Total of KRW 12.9 trillion Orders

Set a new order record of KRW 12.9 trillion for projects in the Middle East, a key market for the company.

The wins included the Raigh 6 project, the company’s largest overseas thermal plant project to date and the Ras Al Khair project,

the world’s largest desalination project to date.

2010, Rotor Shaft for Thermal Low-pressure Turbine Recognized as World-Class Product

The company’s rotor shaft for thermal low-pressure turbines was chosen as the World-Class Product.

2010, CEO Leadership Recognition

hairman & CEO Park who spearheaded Doosan’s successful privatization and transformation into a global company

was highly recognized. He received the prestigious Gold Tower Order of Industrial Service Merit at the 1st

Atomic Energy Day held on December 27, 2010, in recognition of his contributions to the successful win of

the nuclear project in the UAE. Previously, he also received the top award at the CEO Grand Prix Awards in 2009.

2009, Successful “Oxyfuel Testing” by Doosan Babcock

Doosan Babcock successfully demonstrated the world’s first use of oxyfuel in boilers,

using 40MW boilers commonly found in coal-fired plants.

2009, Obtained Core Steam Turbine Technology through the Acquisition of the Czech-based Skoda Power

With its KRW 800 billion acquisition of Skoda Power, Doosan Heavy enhanced its core power product line of boilers,

turbines and generators, becoming a truly vertically integrated global leader in Power.

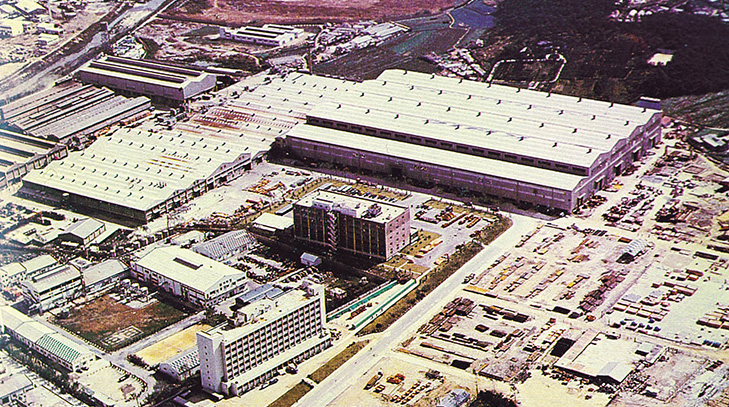

2009, Built Doosan Vina Plant in Vietnam

Opened the KRW 300 billion Doosan Vina manufacturing plant, a large-scale manufacturing plant in central Vietnam.

Composed of five factories and dedicated port facilities, the plant produces boilers, HRSGs, desalination equipment

and material handling systems for projects worldwide.

2008, Announced “Global Leader in Power & Water” Vision with the new President and CEO Geewon Park

After achieving business targets set in 2004 ahead of schedule, Doosan Heavy Industries & Construction was able to ramp up its CSR efforts.

2008, US AP1000™ Nuclear Equipment Orders

Successfully delivered the first shipment of three nuclear units to the US,

a birthplace of nuclear power that resumed the construction of nuclear power plants after a 30-year hiatus.

2008, Nuclear Equipment Order for Shin-Hanul Plant Units 1 and 2

Won an order to supply major nuclear equipment for Shin-Hanul plant units 1 and 2 in Korea.

This project marks the first time Korean nuclear units were produced entirely with domestic technology,

including the Man-Machine Interface System (MMIS) and Reactor Coolant Pumps (RCP).

2008, Strategic Alliance with US-based Burns and Roe

Forged strategic alliance with Burns & Roe, a global leader in engineering and designing of

coal-fired power plants to exchange and share engineering expertise, know-how and talent.

2008, Investment in Carbon Capture Storage

Partnered with subsidiary Doosan Babcock to purchase a 15% equity share ownership

in the Canada-based HTC, a possessor of proprietary CCS technology.

Successful Privatization and Leap (2007 ~ 2001)

2007, China AP1000™ Nuclear Equipment Order

Won an order to supply major equipment for AP1000™ nuclear units for the Sanmen and Haiyang projects,

China’s first third generation nuclear plants, since the company’s entry into the nuclear plant market in China in 1995.

2007, First RO Desalination Order

Won the Shuaibah Phase 3 Expansion RO project in Saudi Arabia, the company’s first RO project.

This project was followed by the Shuwaikh RO project in Kuwait in March 2008 and the Jeddah RO project

in Saudi Arabia in December 2008.

2007, Power Plant Upgrade Order from Australia

Won a turbine upgrade order for the Eraring thermal plant in Australia (660MW X 4 units),

followed by boiler upgrade order in 2009.

2006, Acquired IMGB Romania

Acquired a 99.76% interest in Romania’s largest casting and forging manufacturer Kvaerner IMGB at approximately KRW 14.5 billion.

2006, Signed Contract to Supply Major Equipment for Shin-Kori Units 3 and 4

Won an order for the major equipment for Shin-Kori nuclear power plant units 3 and 4,

Korea’s first nuclear units to adopt the third-generation APR1400 design. APR1400 design offers

dramatically improved safety and efficiency over the previous OPR1000 design.

2006, Established Water R&D Center in Dubai and Tamp

Solidified the company’s position as the global leader in desalination with the development of next-generation large capacity desalination technology.

2006, Won Order for the World’s Largest Coal-Fired Thermal Power Plant in Mundra

Won an EPC contract worth US$ 1.22 billion for the world’s largest 4000MW coal-fired thermal power plant in Mundra, India.

The project was successfully completed in 2012.

Shuaibah Phase 3 Desalination Plant Order from Saudi Arabia

Won an order worth US$ 850 to deliver the Shuaibah Phase 3 desalination plant in Saudi Arabia,

solidifying the company’s position as a global leader. The plant is capable of producing 880,000 tons of

freshwater a day, which can be used by 3 million people simultaneously

2005, Acquired Water Treatment Business of AES of the US

Gained access to source technologies for key parts of the desalination plant in the RO area by acquiring

the water treatment business of AES of the US (currently Doosan Hydro Technology) on October 3, 2005.

2003, Change Vision Announcement

Announced a vision to become a plant specialist, aiming to deliver superior value through

world-class technology and cost competitiveness.

2001, Privatization and Change of Company Name

Changed company name as a private enterprise with a spirit of challenge and innovation and integrated

its CI with Doosan to maximize synergy of privatization.(Photo: Announcement of Fresh Start at Changwon headquarters on May 4, 2001)

2001, UAE Fujairah Desalination Plant Order

Won a US$ 800 million order from UAE state-owned UOG to deliver Fujairah desalination plant.

This project propelled the company to the top of the global desalination market.

In the same year, the company’s desalination plant was chosen as the World-Class Product.

Growth and Development (2000 ~ 1981)

2000, Became Public and Listed on the Stock Exchange

Began to be traded on the stock exchange on October 25 under the stock code 34020.

2000, Doosan Selected Preferred Bidder for Hanjung

A consortium led by the Doosan Group selected the preferred bidder to acquire Korea Heavy

Industries & Construction (“Hanjung”) and Doosan’s acquisition of Hanjung is considered to be the most successful

privatization and M&A in Korea’s history.

1999, Sequoyah Nuclear Plant Order

Won an order for replacement steam generators for Sequoyah nuclear power plant unit 1 in the US,

making the company’s first export to the birthplace of nuclear power 30 years after Korea’s first adoption of nuclear plant technology.

1999, Power Facility Centralization

The Korean government designated one single company to supply power plant facilities in an attempt to restructure

business structure of major companies and promote the nation’s competitiveness in the industry.

1997, Qinshan Phase 3 Nuclear Plant Order

Won an order for steam generators for Qinshan Phase 3 nuclear plant units 1 and 2 in China

from China National Nuclear Corporation (CNNC), the company’s first nuclear equipment sales overseas.

1996, First 800 MW Thermal Plant Equipment Order

Won an order for major equipment for Korea’s first 800 MW Yeongheung coal-fired thermal plant.

1995, Established Joint Venture in Hai Phong, Vietnam

Set up HANVICO, a 70:30 joint venture between Doosan Heavy Industries & Construction and the

state-run heavy manufacturer DMF of Vietnam.

1994, Completed First Korea-Standard Thermal Plant

Completed in April the manufacturing, supply and installation of major equipment such as boilers

and turbine generators for Boryeong thermal plant units 3 through 6, Korea’s first 500 MW coal-fired

thermal project to adopt the standardized design.

1993, Shuaibah Desalination Plant Order from Saudi Arabia

Won an order worth US$950 million from Saline Water Conversion Corporation of Saudi Arabia to build Shuaibah desalination plant.

1987, Order to Supply Major Equipment to Yeonggwang Nuclear Plant Units 3 and 4

Yeonggwang nuclear plant units 3 and 4 are Korea’s first 1,000 MW major plants that adopted the OPR1000 Korean standard plant design.

1985, First Historic Turnkey Seawater Desalination Plant Order

Won an order in January for the Assir desalination project in Saudi Arabia. It was the first turnkey order led by

a consortium with the US-based desalination engineering company ESCO to perform design, manufacturing, installation,

construction and commissioning.

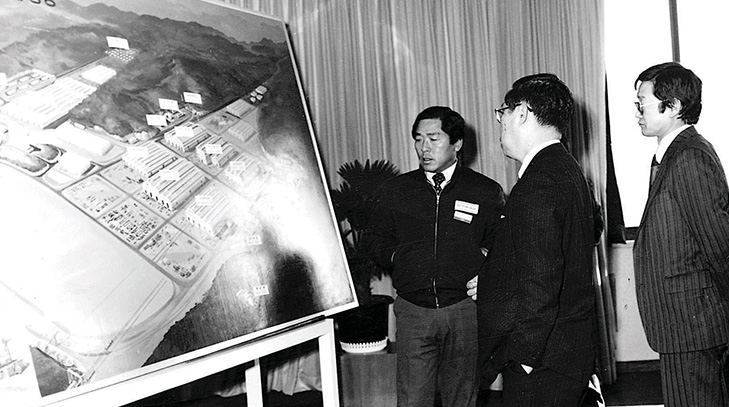

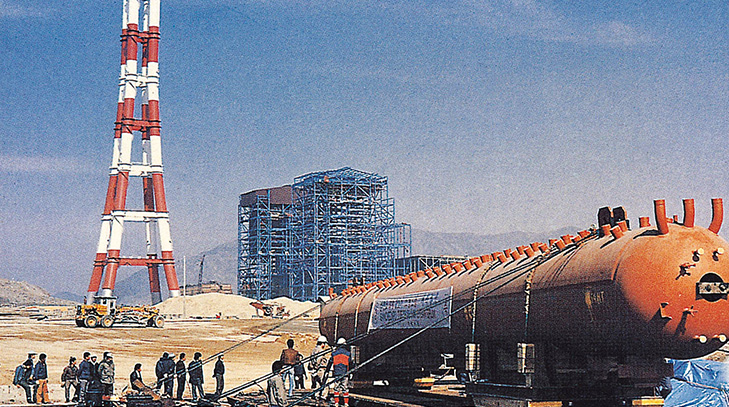

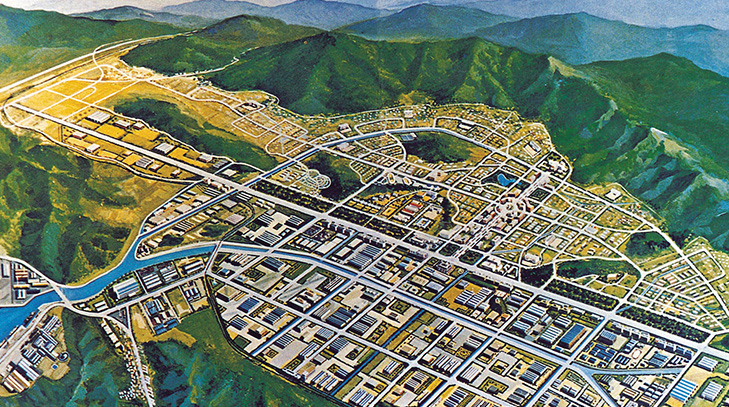

1982, Completed Construction of Changwon Plant

One of the world’s largest integrated manufacturing plants at the time,

Changwon Plant construction was finished six years after the groundbreaking in 1976.

The Changwon Plant opened a new chapter in Korea’s industrial plant sector as the engine

behind the company’s growth. (Photo: The completion ceremony of Changwon Plant received big

attention with the attendance of the country’s president.)

1982, Korea’s Only 13,000-ton Press in Operation

Changwon Plant was a far-sighted investment, having the world’s largest 13,000-ton press facility at

a time when casting production lines were almost nonexistent.

Business Establishment (1980 ~ 1962)

1980, Nationalization

Renamed Hanjung as a government-invested public enterprise.

1979, Korea’s First Bituminous Coal-fired Samcheonpo Thermal Plant Units 1 and 2 Order주

Won a turnkey order for Samcheonpo thermal power plant 560MW units 1 and 2, Korea’s largest coal-fired thermal project at the time.

With this project, the company began to accumulate technological expertise.

1978, First Desalination Project, Farasan

Won an order to supply equipment to the Farasan project in Saudi Arabia, the company’s first desalination project.

1976, Groundbreaking of Changwon Plant

In step with the government’s heavy chemical industry promotion policy,

the company embarked on a historic project to build Changwon Plant.

1973, Built Gunpo Plant

Built Gunpo Plant in Gunpo, Gyeonggido, to produce castings, machinery and forgings,

paving the way for the company’s growth into a machinery and heavy industry company.

1962, Founded Hyundai Yanghaeng

Established on September 20, 1962 as Hyundai Yanghaeng, the company started out as a trading firm,

importing raw materials and equipment for manufacturing and construction as well as cement.