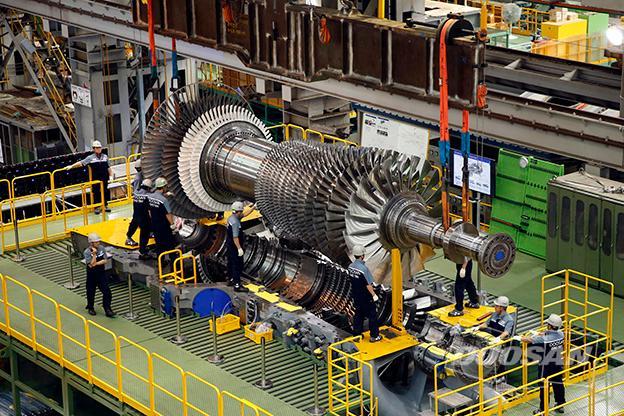

- □ The imposing figure of Korea’s first independent large gas turbine model for power generation has finally been unveiled to the public. Doosan Heavy Industries & Construction (DHIC) announced on September 19 that it had held the final assembly event at the head office in Changwon for the first large gas turbine for power generation. It’s currently being developed as part of a national project sponsored by the Ministry of Trade, Industry and Energy and the Korea Institute of Energy Technology Evaluation and Planning. Currently about 95% complete, it is expected to undergo an in-house performance test by the end of this year. Once it has passed the test, Korea will become one of the five countries along with the United States, Germany, Japan, and Italy to have secured independent gas turbines for power generation

- □ DHIC has actively participated in the government’s national project to develop the Korean standard gas turbine model since 2013. The purpose of the project is to develop a unique Korean model of gas turbine for power generation in order to overcome the country’s dependence on foreign imports. The government has invested about KRW 60 billion in the project, while DHIC has invested around KRW one trillion in R&D. The national project is considered a model case of technology development through industry/academia/research cooperation, as 21 colleges, 4 government-funded R&D institutes, 13 small and medium enterprises/middle market enterprises and power plant operators have participated in it along with DHIC.

● Gas turbine for power generation considered the “pinnacle of mechanical engineering” … Requires more advanced technology than a jet engine

- □ The DGT6-300H S1 developed by DHIC is a large-capacity, high-efficiency gas turbine consisting of more than 40,000 parts, with a power output of 270 MW and combined generation efficiency of more than 60%. A turbine contains more than 450 blades, the price of each one being almost equal to that of a mid-sized car.

Since an LNG power generator emits just one eighth the amount of fine dust (PM 2.5) emitted by a coal-fired power generator, and releases just one third the amount of air pollutants such as sulfur oxides and nitrogen oxides directly into the atmosphere, the DGT6-300H S can be operated in an eco-friendly manner. - □ A gas turbine for power generation can be considered “the pinnacle of mechanical engineering” as it requires advanced technologies in many areas. Recent gas turbines integrate the most complex mechanical engineering technologies, including an ultra-heat-resistant alloy material technology that continuously withstands harsh operating conditions of 1500 ℃ or higher; a precision casting technology for producing complex parts that have to operate under high temperatures; an axial compressor technology that compresses a large volume of air to up to 24:1; a combustor technology that minimizes exhaust gas; and a system integration technology for assembling the core components of the compressor, combustor, and turbine.

- □ “Although the gas turbine for power generation originated from the aircraft jet engine, its technology has had to advance rapidly to meet the strict market requirements. Some technologies, such as the advanced material technology needed to guarantee stability and durability at high temperatures of 15000C or higher, which was applied to the 270 MW model, have surpassed jet engine technology,” declared Dr. Jong-wook Lee, a center director at DHIC.

- □ 이The new model will be supplied to the 500 MW Gimpo Cogeneration Plant to be constructed by KOWEPO and enter into commercial operation in 2023. In addition to this model, DHIC plans to develop a follow-up gas turbine model (380 MW) with the latest specifications to preemptively reflect the market changes, and a 100 MW mid-sized model designed to supplement intermittency, which is considered a great shortcoming of renewable power.

● Korea wholly dependent on imported gas turbines in the past ... Expects to replace imports of about KRW 10 trillion by 2030

- □ A total of 149 gas turbines are currently operating in power plants in Korea, all of which were imported. Considering the purchasing cost of about KRW 8.1 trillion and maintenance, auxiliary, and other costs of about KRW 4.2 trillion, the combined cost of all turbines is about KRW 12.3 trillion. Furthermore, given the announcement of the 8th Master Plan for Power Supply and Demand at the end of 2017, the obsolescence of current cogeneration plants, and the re-powering of coal-fired power plants, the total capacity of the new cogeneration plants equipped with gas turbines to be constructed by 2030 is expected to be about 18 GW.

The use of domestic gas turbines at all of the 18GW cogeneration plants would be equivalent to a total import substitution effect of about 10 trillion won (based on USD 480.1 per kW and KRW 1150 per USD). - □ The advantages will be even greater if the service business of maintenance and parts replacement and the entry into overseas markets are added to the equation. IHS Cambridge Energy Research Associates (CERA) of the US has forecast that many new gas power plants with a total capacity of 432 GW will be constructed worldwide between 2018 and 2028. DHIC plans to develop the gas turbine into its main line of business in a bid to generate annual sales of KRW 3 trillion and create more than 30,000 jobs by 2026 by adopting aggressive sales programs in Korea and abroad.

- □ DHIC has steadily invested in developing its gas turbines into its main business line. It has opened an R&D center dedicated to the development of large gas turbines for power generation at its head office in Changwon as well as in Florida, USA and Baden, Switzerland, and has also built a full speed and full load test center in Changwon for an investment of more than KRW 100 billion. The test center can carry out comprehensive performance tests by monitoring gas turbine vibration, stress, and pressure, as well as the temperature of fluids and metals, with more than 3,000 sensors.

- □ DHIC has also been preparing to penetrate the gas turbine service market. Gas turbine manufacturers have continuously created post-supply income from the service business, which encompasses maintenance and parts replacement. In 2017, DHIC acquired DTS (Doosan Turbomachinery Services), which carries out the entire service business including maintenance, parts replacement, and performance improvement of the core parts of gas turbines in the United States. DTS now has the know-how to service most gas turbine models currently in commercial operation in Korea.

- □ “DHIC has strived to diversify its business portfolio amid the rapidly changing market environment, and the development of a new gas turbine for power generation is one of the critical outcomes of its long-term effort. We plan to achieve meaningful outcomes in other areas by pursuing continuous change and innovation,” said Geewon Park, the chairman & Chief Executive Officer of DHIC. “The development of the gas turbine is also significant in that it will lead to the creation of a new industrial ecosystem in which some 230 small and medium enterprises/ middle market enterprises in Korea will be able to participate,” he added.

● DHIC ready to penetrate the gas turbine service market with the independent model