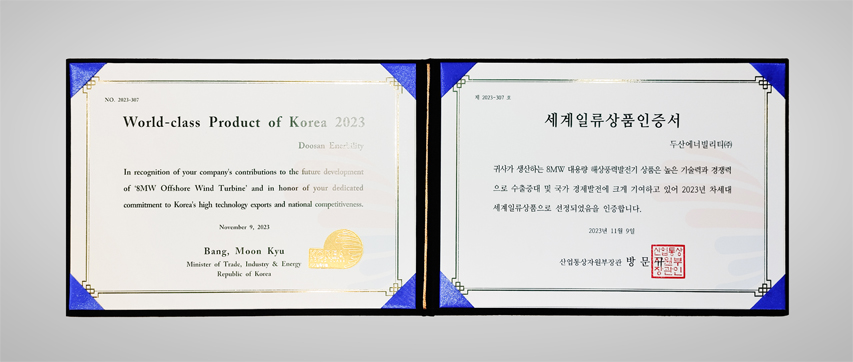

Doosan Enerbility announced on November 10th that its 8MW offshore wind power system (DS205-8MW) had been selected as a “Next Generation World-Class Product. “

As an initiative that was devised for the purpose of promoting Korea’s exports, Korea World-Class Products refer to products and companies that were certified as being of world-class level by South Korea’s Ministry of Trade, Industry and Energy (MOTIE) and Korea Trade Investment Promotion Agency (KOTRA). The products are categorized as either “World-Class Products” which refer to those rated as being within the Top 5 in terms of global market share and have a market share of 5 percent or more, or “Next Generation World-Class Products,” which are items deemed as having the potential to become “World-Class Products” within the next seven years.

Doosan’s 8MW offshore wind power system, which is a wind turbine that was developed using Korean homegrown technology, has already undergone a demonstration project and obtained international certification.* Being highly recognized for its projected future contribution to the industry, Doosan’s offshore wind turbine was selected as a Next Generation World-Class Product. The wind turbine was specially designed to suit the Korean environment, which has notably lower wind speeds compared to Europe where offshore wind power is well-developed. The diameter** of the rotor was lengthened to 205 meters (blade length: 100 meters), so that the wind turbine could be used even when the average wind speed is 6.5 m/s, thereby making it possible to record a utilization rate over 30 percent.* Obtained UL Type Certification in 2022.** Rotor diameter refers to the diameter of the circle drawn by the tip of the turbine blade. The longer the diameter, the larger the surface area of the blade for receiving the wind, leading to higher power generating efficiency.

“The recently selected 8MW offshore wind power system is a product that was developed as a state-led project and it was with Korea’s local technology that we completed the design and manufacturing of the main components such as the blade and generator,” said Hongook Park, CEO of Doosan Enerbility’s Power Services Business Group. He added, “With nearly 70 percent of the components being manufactured locally, we aim to actively pursue further market expansion in order to create more jobs across the overall Korean wind power industry.”